A reliable OEM manufacturer for large and small businesses

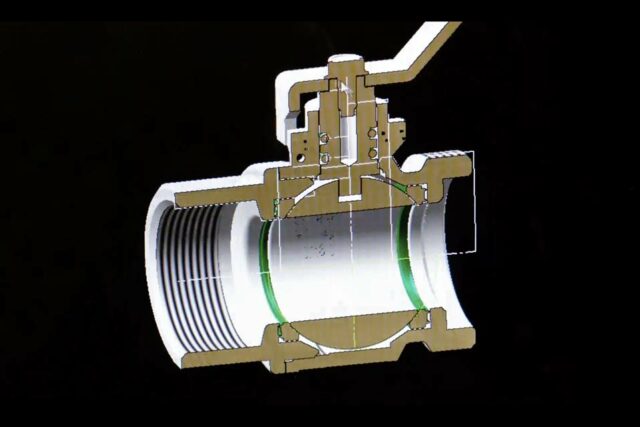

Every day, large international manufacturers but also small local companies use our OEM production of ball valves and brass fittings. We offer both the supply of basic components and the production of complex and finished pieces, ready for sale.

Start your white label production

We are able to provide different types of collaboration based on the needs of your project. The two most typical cases of collaboration are production based on specific requests or on the basis of project provided.

option 1 Production based on the requested performances

We design and manufacture components based on specific requests or desired performances, putting our 40 years of experience in the field.

option 2 Production according to the project provided

We make the components according to the project supplied by the customer, with the possibility of concatenating a high number of complex processes and arriving at finished products, branded and ready for sale.

The ideal partner

for your OEM production

We are the ideal partner to start a supply of OEM components, both for large projects and limited-edition productions.

01 Experience and quality

Fornara production combines the high technology of the machinery and the great specialization of our workers and technicians. From this set of technology and human factor comes the quality of our components that proudly represent the real Made in Italy.

A high-level production cannot be separated from quality materials. We select our suppliers and we have a vast choice of materials, all of certified Italian quality and origin, which allow constant quality production.

Our choice of materials goes beyond the standard supply and provides for different alloys and types of processing. The advantage for the customer is the ability to customize every aspect of production and work for different markets and different standards.

02 Flexible and reliable production

Versatile and constantly renewed machinery poolOur machinery pool is large and diverse and allows numerous types of machining. We frequently update machinery by constantly introducing new technologies.

Fast on complex processesThe variety of our machinery allows us to create complex components in competitive times. The supply of transfer machines with over 10 stations allows us to make complex processes with few cycles while maintaining high production efficiency and speed.

Delivery times protected from unexpected eventsWe have a large and well-organized warehouse and a great experience in optimizing production. We create and repair internally the tools with which we manufacture the components and we always have several families of components and materials ready in stock. All these choices and optimizations allow us to make the machines work without interruption maintaining the agreed delivery times.

03 Highly Competitive

Very competitive price-performance ratioFew Italian manufacturers are able to offer our quality/price ratio by balancing the quality of materials, production processes and level of finishes.

Ready for changeFew Italian manufacturers can offer our quality / price ratio by balancing the quality of materials, production processes and level of finishes.